When you work with a provider to produce electronic enclosure assemblies, value added services, battery packs or a certain type of cable assembly, there are a number of criteria you want them to meet. For example, the wiring harness should be designed and developed to effectively address your functional requirements (e.g. impedance or dielectric strength). In addition, the project — from design to prototype production to producing the cable assembly in quantity — should be cost-effective and stay on budget. What’s more, the completed product should be delivered according to your timeline. However, achieving all of these objectives is not Read More

Category: Custom Services

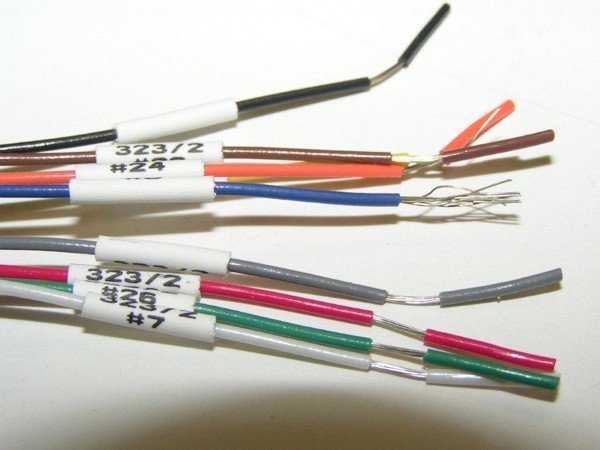

What You Need to Know About Wire Harness Assembly Labeling

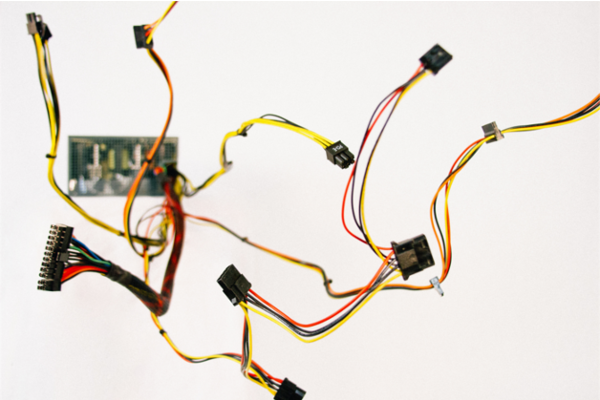

A wire harness assembly (also known as a cable harness, cable assembly, wire bundle, or wiring loom) is a group of electrical wires or cables held together with conduit, cable ties, straps or by other means. It is used to provide power or data to a particular device or system. While the fact that the wires are bound together makes it easier to decipher what should be connected at each end, it can still be very helpful to have the wires labeled. This can mean labelling individual wires within a group, multiple wires, or the entire bundle. What a Wire Read More

Custom Wiring Harness Uses

Wire harnesses have exceptional versatility. Consequently, they can be used in a wide range of industries and for many purposes. Learn more about those uses here! Read More

4 Surprising Things You Didn’t Know About Batteries!

Did you know the first official battery was created due to a disagreement about frog legs? Your laptop, cell phone, car and TV remote are all likely powered by batteries. But how much do you really know about batteries and their history? Read More

Include Inclement Weather in Your Materials Planning Forecasts

Unpredictable inclement weather can impact product shipments. Communicate materials forecast planning needs to customer service to counteract the unpredictable. Read More

Custom Wire and Cable Services

As you have read in previous blog posts, Rapport offers a long list of manufacturing services—from manufacturing custom cable assemblies to building battery packs to customer specifications. But did you know that we also offer customization of your wire and cable before we incorporate it into your custom assembly? Following are a few of the custom wire and cable services available at Rapport, inc. Striping – We offer custom striping on PVC, teflon, nylon, and irradiated material. 1, 2, or 3 stripes can be applied to wire or cable ranging in size from 8 AWG – 30 AWG. Twisting – Twists are available on wire Read More