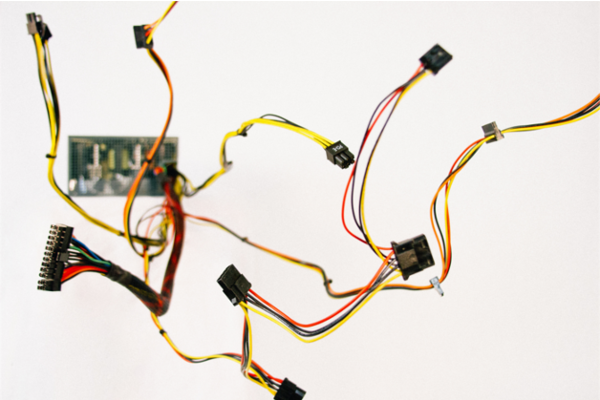

A custom wiring harness, also called a cable harness, is an assembly that holds together wires. These wires are used to transmit power or signals to or within a device. The use of a custom wiring harness provides many advantages over simply leaving wires loose.

For example, wires bound together have more strength and binding them also minimizes abrasion that can damage them. This is especially important in devices that produce or are exposed to vibration. Another important benefit is ease of installation. With ease of installation comes a savings in labor, which can translate to net savings even with the cost of a custom wiring harness. A technician can be much more efficient when working with a wire bundle as opposed to an unruly clump of wires.

Harnesses can utilize a variety of materials including nylon, PVC, and Teflon®, and the wires managed can be cut, dyed, and stripped to your specifications. Plus, harnesses can be used to control a wire bundle made up of a few strands or thousands of wires. Also a boon to efficiency and cost savings; finished assemblies can be labeled with heat shrink tubing or laser-printed sticky labels and bundled for easier handling and distribution.

In short, wire harnesses have exceptional versatility. Consequently, they can be used in a wide range of industries and for many purposes.

Where is a Custom Wiring Harness Used?

The electronic devices in virtually any industry can benefit from having custom wiring harnesses incorporated into their designs. According to the Wiring Harness Manufacturer’s Association, some of the markets most likely to take advantage of wire harness assemblies include:

- Agriculture. In order to increase productivity while controlling costs, farmers and ranchers are adopting advanced technology at a rapid rate.

- Appliances. Global demand for well-made appliances and the wire assemblies that power and control them continues to grow.

- Automotive. The auto industry is a leader in innovative ways to use high-quality wire harnesses.

- Computers/peripherals. With intense competition in their market, makers of computers and peripherals need wire bundles that support performance and reliability.

- Electronics. Original Equipment Manufacturers (OEMs) looking to control costs are increasingly outsourcing the design and production of items like wiring harnesses to Electronics Manufacturing Services (EMS) partners.

- Marine. Marine environments can be very hostile. Consequently, companies operating in this space often need custom waterproof wire harnesses designed specifically for their requirements.

- Medical. Ongoing advances in medical technology continue to require the development of customized electronic assemblies.

- Military. From an aging domestic airliner fleet to skyrocketing drone production to the ever-evolving needs of the military, custom wire harnesses are always in demand.

Unique Custom Wiring Harness Uses

Rapport produces wire assemblies for many different uses. Some of the more interesting and challenging applications we’ve tackled include:

- Cable assemblies for advanced laser measurement products

- Waterproof assemblies for use in automatic car washes

- Cable assemblies used in high-resolution laser engraving and cutting systems

Ultimately, if you market a device that has unique requirements for its electronic assemblies, you want to work with a wire harness manufacturer like Rapport that has decades of experience in the industry.

Our full-service facility outside of Denver can help you develop the custom wiring harness you need, from prototype to final packaging, quickly and cost-effectively. Contact Rapport, Inc. today to get answers to all of your questions about wire bundles!