Shopping around for cable assemblies can be challenging. You’re typically looking for something completely custom to handle a unique problem just for your business. To make sure you are getting exactly the assembly you need, we’ve compiled 5 of the most common cable assembly types and the type of applications you may need them for.

Military Grade Cable Assemblies

When you think of things that are military grade, you may imagine something rugged, simple, and fine with being dropped off a helicopter. You’re mostly right – military grade cable assemblies are typically used for tactical and marine applications. There are a number of strict requirements for cable assemblies marked as military grade, and a separate set of requirements for the connectors on your cables and the wires used in the assembly. Additionally, the use of the cable assembly is taken into account; the requirements for cable assemblies that will be used in underwater environments are totally different than those used on planes. Military grade cable assemblies are often required for field communication links, airborne systems, remote weapons control, marine systems, military ground equipment, and inter-shelter communications.

RF/EMI Cable Assemblies

We live in an incredibly noisy world – and each of your cables is probably adding to that noise. RFI is radio frequency interference that occurs on the radio frequency spectrum. EMI references electromagnetic interference. “Both man-made and natural sources generate changing electrical currents and voltages that can cause EMI: ignition systems, cellular network of mobile phones, lightning, solar flares, and auroras Northern/Southern Lights.” (Wikipedia.org). “The disturbance may degrade the performance of the circuit or even stop it from functioning. In the case of a data path, these effects can range from an increase in error rate to a total loss of the data.” There are applications where you may want to leverage these signals, and times when you may not want them. You’ll want to work with your cable assembly creator to figure out what is best for you.

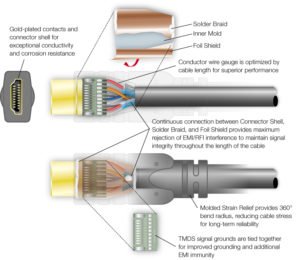

Molded Cable Assemblies

You probably have seen a number of molded cable assemblies in your non-work life. HDMI cables are typically molded cable assemblies. Below you can find an image of an HDMI cable underneath the molded shell. Molded assemblies are typically used in applications where a more durable and finished appearance is desired so if those are your requirements, a molded cable assembly may be the way to go.

Shells can be made of plastic or metal, can be shielded or unshielded, and can be used in a wide variety of applications.

Assembled Coaxial Round

Coaxial cables or “coax” cables have been around for a very long time – they work really well. Additionally, you almost certainly have one or more coax cables in your house already – they are the stabby usually black cables you plug into your TV to get cable (or hide behind a piece of furniture because no one has cable anymore).

A Coaxial cable “is a type of electrical cable that has an inner conductor surrounded by a tubular insulating layer, surrounded by a tubular conducting shield. Many coaxial cables also have an insulating outer sheath or jacket. The term coaxial comes from the inner conductor and the outer shield sharing a geometric axis.” Some of the uses for coax cables include cable internet, and applications in vehicles, aircraft, medical equipment, and radios.

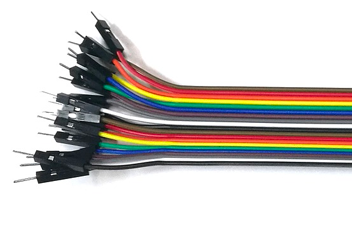

Flat Ribbon Cable Assemblies

Flat Ribbon cables look really cool. Rather than the wires being bundled together within a sheath, the wires are nicely organized in a flat ribbon. If you’ve ever opened up a really old computer you may have seen a ribbon cable – they are mostly no longer used in computers as they are large and hard to fit in a tiny case but they are just as effective as round cables, and have applications where a flat cable assembly may be more advantageous than a round one. With a ribbon cable, you can color code each wire to know what they do, as well as see each wire individually. “The main point of ribbon cables is to allow mass termination to specially designed IDC connectors in which the ribbon cable is forced onto a row of sharp forked contacts.” Ribbon cable assemblies may be more durable than their round cable counterparts, and are great for usages where the width of the cable is important.

Our full-service facility in Colorado manufactures custom cable and wire harnesses from prototype to final packaging, quickly and cost-effectively. Rapport can manufacture any custom cable or wire harness assembly to your specification. Contact Rapport, Inc. today to get your custom cable assembly started!

Great Blog and nice information you shared about types of Cable Assemblies. keep sharing.

Thanks for reading our blog! We’re glad you enjoyed our post.

I’d like to thank you for your explanation about these cable types. It really helped when you discussed them in full details. I am not that good at identifying and even remembering cables, so this is really a big help, cheers!

It’s interesting to learn that there are several types of cables to choose from depending on your business needs and having them made assembled customarily makes an ideal setup to match the setting that you have in your establishment. It makes sense because there are areas where we can plug in our gadgets such as laptops so we can work comfortably in one space. If I were a business owner, I’ll make sure to address these issues before my office space becomes operational by seeking the help of an expert in custom cabling. I know that there’s an art to it that only the experienced individuals can make it work so hiring one will certainly be worth it.