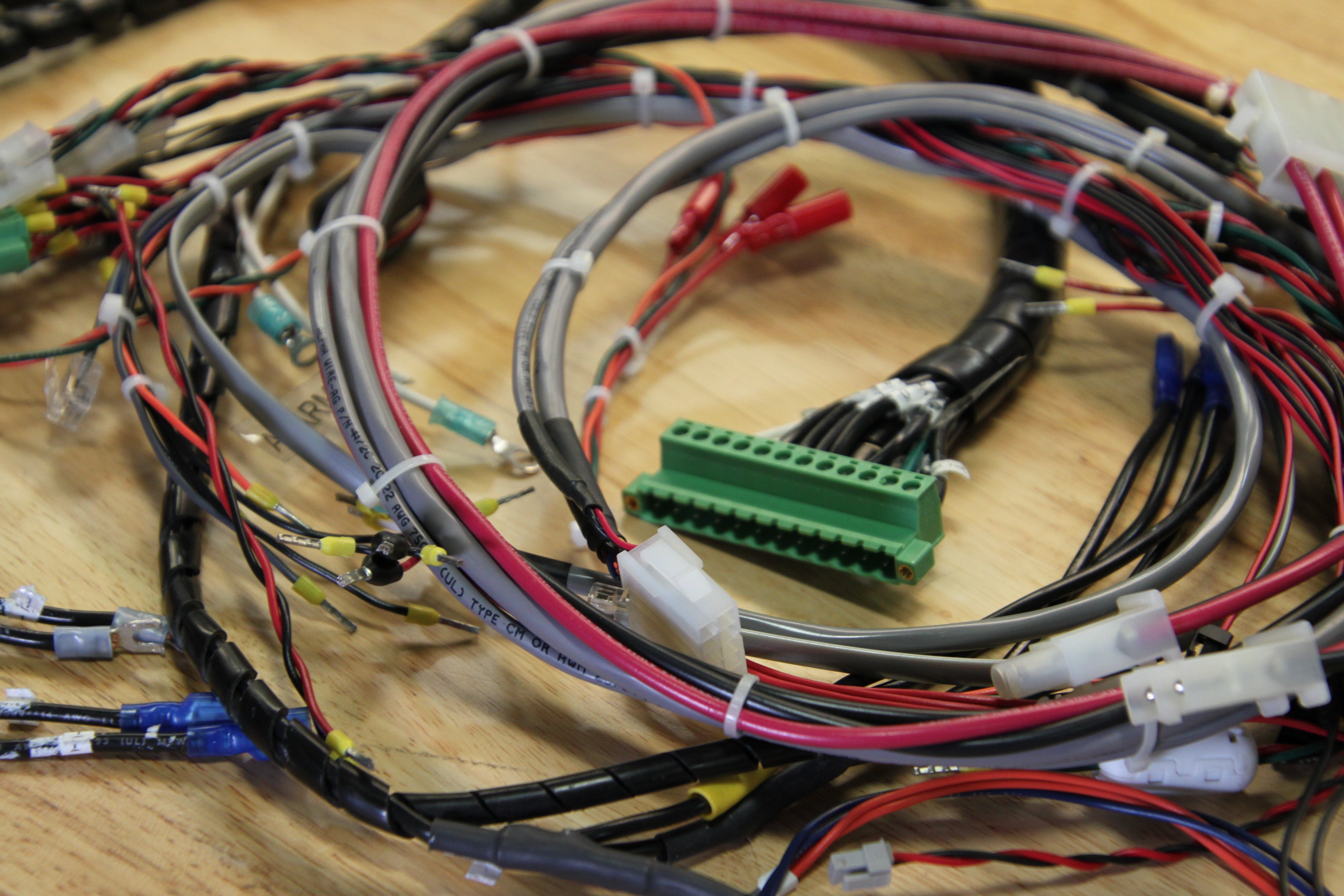

In manufacturing, a “first article” is an initial piece produced so that a customer can confirm that the assembly has been built precisely to their written specifications. In the development of a custom wiring harness or cable assembly, for example, coming to an agreement on whether the finished product adheres to the specifications provided before a production run is initiated is critically important. Doing so ensures that the customer’s investment in the parts will be money well-spent and helps prevent the need for significant rework.

Bringing Extensive Expertise to Bear on Custom Wiring Harness First Articles

In order to ensure that our custom wiring harness or cable assembly first articles are produced with the highest level of expertise, we assign these projects to one of our production floor managers or senior assemblers. The manager works closely with the customer to understand the company’s needs and the specifications for the finished cable assembly. It is important to get those details squared away even before the first article is produced.

Once the first article has been developed, the manager follows the same proven quality assurance process we use during production runs. This process drives how we inspect and test the item prior to sending it to the customer.

After we have tested the finished wiring harness, the customer assesses it both for overall quality and to determine if it meets their specifications. Approving a part that deviates from the specs by even a small amount, or that doesn’t meet a requirement that may have been left out of the original specs, can delay production, and that delay can produce a ripple effect that has wide-ranging impacts on the business.

In some cases, upon review of the first article, the product requirements for a custom wiring harness or cable assembly are modified and a new first article is produced. Then, the internal inspection and customer evaluation process is repeated. Once a finished product gets the customer’s “stamp of approval,” production can begin.

Two First Article Scenarios for a Custom Wiring Harness or Cable Assembly

When a customer comes to Rapport to have the first article produced for a custom wiring harness or cable assembly, there are two primary scenarios.

In the first, the customer has an engineering drawing or print for the assembly. In that case, we can produce a first article for review and approval. That is our preference, as it ensures we are in agreement with the customer on the specifications and also allows our production manager or senior assembler to make recommendations regarding things like the size of the heat shrink, the length of the wire or the size of the terminal. Sometimes, the customer may waive the first article and request Rapport move directly to production using the provided engineering drawing or print. In doing so, the customer accepts responsibility for any specification-related issues with the production run.

In the second scenario, there is no engineering drawing or print. Instead, the customer has a sample or possibly even just a photo or sketch of the item. In this case, of course, a first article is required. In fact, multiple first articles may be needed to zero in on the product characteristics that the customer needs.

Cable Assembly First Article to High-Volume Production in One Facility

In some manufacturing projects, a customer may either create a first article in-house or work with one contract manufacturer to get a first article developed and then turn to another contract manufacturer to have the parts produced en masse. At Rapport, we have the ability both to work through the first article approval process on a cable assembly or any item we offer, and then to scale up to produce the item in large quantities.

There are multiple benefits to this approach. For example, when the same company creates a first article and does production runs, nothing about the product gets “lost in translation.” Also, the transition from testing to production can take place faster, as no knowledge transfer is required.

The Advantage of Experience in Cable Assembly First Articles

Producing the first article for a cable assembly or custom wiring harness requires more than just the ability to read and follow an engineering drawing or print. There are many nuances to product development that only come with time and experience.

We’re pleased to be able to offer our customers the skills and expertise of team members who have been with us as long as 22 years and on average, 8 years. Additionally, many of these team members have prior industry experience from working for other employers. The result of this vast experience is a first article process that delivers assemblies that are tested and ready for customer review more quickly and that adhere more closely to the customer’s requirements.

Our full-service facility in Colorado can take a custom wiring harness or cable assembly from prototype to final packaging, quickly and cost-effectively. Contact Rapport, Inc. today to get your project started!