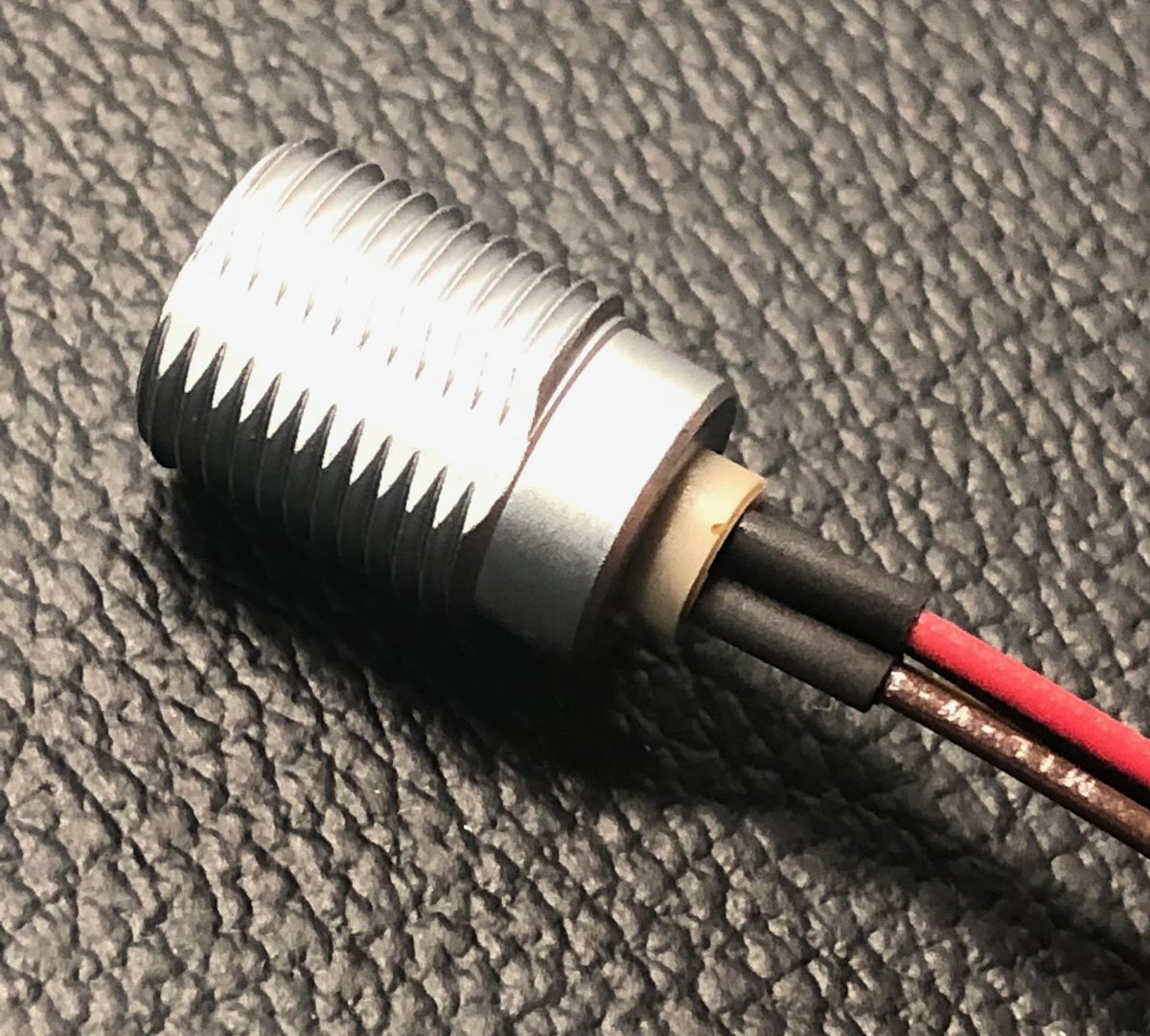

A cable harness, also known as a cable assembly, wiring harness, wire bundle, or wiring assembly, is a collection of cables or wires that are secured into a single unit and have a connector at one or both ends. They are used to transmit power or informational signals in electronic devices. A cable harness serves many purposes.

First, it makes it easier to install a group of wires. Technicians only have to make one connection rather than doing so for each individual wire. Second, a cable assembly is easier to locate and replace than multiple independent wires or cables. Also, by holding the group of wires together, a cable harness is more space-efficient within tight enclosures.

Protecting Cable Harnesses

In situations where a cable assembly will be used in harsh conditions, the wires are typically protected in some way. Some of the many options for protecting or shielding the cables include:

- Heat shrink tubing. This material holds the wires together firmly and can provide electrical insulation or thermal protection. It may also protect against chemical corrosion or water damage.

- Spiral wrap tubing. This type of wrap has openings that allow wires or cables to join or separate from the group along its span.

- Split loom tubing. This form of tubing is made with a small opening that runs its length and through which wires are installed. After installation, the slit closes, keeping the wires surrounded.

- Sleeving. Some sleeving expands down the length of a set of wires. and other forms are wrapped around the wires. Sleeving can be made of material like braided polyethylene, which is flexible even at very low temperatures.

- Tape. Cable harness tape can have many different types of backing including PVC, foil, felt, foam, and cloth. It can be applied manually, using a manual-feed machine, or using fully automated systems.

Of these, heat shrink tubing is one of the most commonly used protective covers.

10 Key Features to Consider in Heat Shrink Tubing

There are many types of heat shrink tubing that can be applied to a cable harness. In selecting the one to best meet your needs, you should keep the attributes below in mind.

- Temperature tolerance. Some tubing is better at resisting heat. If your product will be used in a hot environment, it is critical that the tubing material is properly heat rated.

- Chemical resistance. What kinds of chemicals is the cable assembly likely to come into contact with? Solvents? Acids? Fuel? The answer will affect your selection.

- Strength. The material you choose must be rated with a tensile strength sufficient to protect against breakage in the device.

- Abrasion resistance. If the cable harness will be exposed to friction, it is critical that it not erode and expose the wires.

Electrical insulation. What is the dielectric strength of the material? This number will help you assess how much voltage the tubing will be able to handle. - Flexibility. Heat shrink tubing runs the spectrum from very flexible to nearly rigid. Often the size of the area into which the cable harness will be installed affects the decision on flexibility.

- Water resistance. Will the assembly be exposed to water? If the cable assembly will be exposed to water, what type? Fresh water? Salt water? The right tubing can provide protection.

- Shrink factor. Every material shrinks to a different degree. It is important to know what kind of ratio you need and what the material provides.

- UV protection. An assembly that will have frequent or ongoing exposure to sunlight must have a UV-resistant tubing.

Flame resistance. Is it possible that the cable assembly will be exposed to flame? If so, you must select a tubing with the appropriate UL rating.

Customized Cable Harnesses Properly Protected

Given the time and effort that goes into designing, manufacturing, testing, and installing a particular wire harness, it is vital that the assembly is properly protected. The right type of heat shrink tubing can help keep the wires safe under the expected environmental conditions.

Our full-service facility outside of Denver can create a cable harness from prototype to final packaging, quickly and cost-effectively. Contact Rapport, Inc. today to get answers to all of your questions about your next cable assembly production project!