You have an item, and you know you need to get power and control to it somehow, but what exactly do you need? Whether your product will go to work in the medical field, manufacturing, or a public utility, you likely will need a cable harness or wire assembly.

What is a Cable Harness or Wire Assembly?

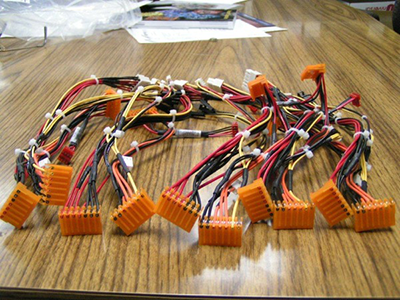

“A cable harness, also known as a wire harness, cable assembly, wiring assembly or wiring loom, is an assembly of electrical cables or wires which transmit signals or electrical power. The cables are bound together by straps, cable ties, cable lacing, sleeves, electrical tape, conduit, a weave of extruded string, or a combination thereof.” (Wikipedia.org). In layman’s terms, a cable harness/wire assembly is simply a collection of wires and cables that are organized neatly to help control and or power a device.

Why are people making these assemblies and not robots?

It is possible to automate some parts of the wire or cable assembly production, such as cutting wire to length, but it is difficult to automate the many small processes that go into creating a cable or wire assembly. Processes include routing wires through sleeves, crimping terminals onto wires (and crimping multiple wires onto one terminal), and fastening strands to each other.

Rapport uses hand held crimpers and automated crimping machines. Automated crimping provides consistent quality, a better held crimp, and is faster when performing large, repetitive jobs. Hand held crimp tools offer a good hold and are primarily used for small, specialized jobs. Rapport has a vast line of terminals, terminal head sets, and automated machines and a team of trained crimpers and solder professionals ready to tackle any size project.

Choose Rapport for your custom prototype and production cable or wire harness needs. We can provide the best value from start to finish. Please call us at (303) 202-9599 or contact us for more information specific to your project.