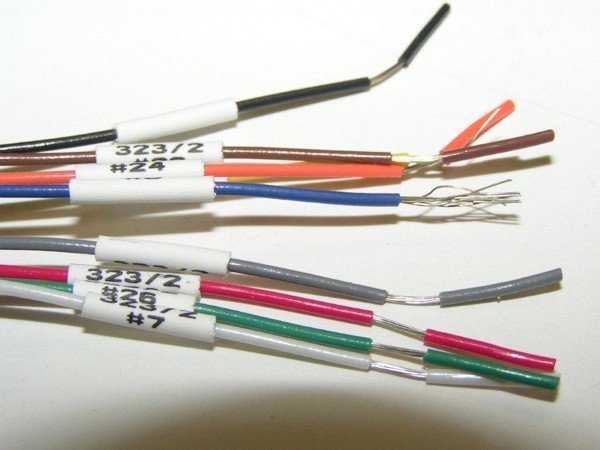

A wire harness assembly (also known as a cable harness, cable assembly, wire bundle, or wiring loom) is a group of electrical wires or cables held together with conduit, cable ties, straps or by other means. It is used to provide power or data to a particular device or system. While the fact that the wires are bound together makes it easier to decipher what should be connected at each end, it can still be very helpful to have the wires labeled. This can mean labelling individual wires within a group, multiple wires, or the entire bundle.

What a Wire Harness Assembly Label Can Tell You

In labeling the wires in a wire harness assembly, you can communicate information in a variety of ways. This includes through:

- Barcodes. There are many barcode formats (Code 39 Full ASCII, Code 128, QR Code, MIL-STD Labeling, etc.) that can be used to provide information in scannable form to anyone handling or working with a wire bundle.

- Text. Details such as a date code, product identification number, or other information can be printed on a label that is secured to the appropriate wire or wires.

- Certification codes. If a wire harness assembly is used in a UL-certified product, the wire bundle can have a UL or CSA tag applied.

Is Color Coding of Wires Enough?

In some cases, simply building a wire harness assembly out of different colored wires is sufficient. However, the colors used by one organization may not be the same as those used by another, causing problems if a wire bundle must be integrated into the second company’s product. There is much less risk of confusion if individual wires or groups of wires are labeled with numbers, words, or images.

Types of Labels for Wire Bundles

There are many ways to label a wire bundle, depending on how the wire harness assembly will be used. Some of the most common methods are:

- Printable thermal transfer self-laminating (THS) wraparound film labels. Made from polyester or vinyl, these labels have a white area for printing information and a clear tail that is wrapped around wires.

- Self-laminating laser printable polyester film labels. These low-cost labels have a UV-resistant coating and are for general indoor or outdoor use.

- Thermal transfer printable heat shrink wire marker sleeves. This type of labeling provides military-grade permanent identification that is extremely durable.

A wire harness assembly manufacturer like Rapport can help you understand the pros and cons of each type of label so that you choose the format that best meets your needs.

Labeling by Materials Providers

In some cases, it is most efficient to have the provider of a particular type of wire or cable label the material before it is received by the wire bundle manufacturer. The provider can apply text or graphics to the material through laser printing or hot stamping. Laser printing is typically used on PVC or Teflon surfaces. Hot stamping is when images are embedded into the wire coating, making the information very wear resistant.

The Benefits of Getting Wire Bundle Manufacturing and Labeling in One

While a company can label its own wire harness assemblies, or have a third party perform the work after the assembly has been built, there are many advantages of working with a provider that can both produce the wire bundles and label them. This includes:

- Greater efficiency. Having a wire harness assembly built and labeled within the same production environment is much more efficient than requiring each harness to be handled again.

- Increased agility. If you have to quickly change the format or content of a label, it is much easier with an all-in-one operation.

- Decreased risk of incorrect labeling. The company that manufactures your assembly will have a good understanding of what it is to be used for. This knowledge can help prevent a miscommunication about how particular wires or groups of wires should be labeled.

Our full-service facility in Colorado can ensure your wire harness assembly is properly labeled as we take it from prototype to final packaging, quickly and cost-effectively. Contact Rapport, Inc. today to get your wire harness assembly project started!